International Women’s Day 2023: How One Woman in India is Helping Female Better Cotton Farmers to Thrive

While women play a pivotal role in the cotton sector across the world, they are frequently held back by many forms of discrimination, leading to underrepresentation in decision-making, lower wages, less access to resources, limited mobility, increased threats of violence and other serious challenges.

Gender discrimination is a key issue in the cotton sector, which is why ensuring that all workers enjoy decent working conditions, with fair pay and equal opportunities for learning and progression, is a top priority for Better Cotton, laid out in our Principles and Criteria.

This year, in recognition of International Women’s Day, we want to celebrate those building workplaces where women can thrive. In order to do so, we spoke with Manisha Giri, a Producer Unit Manager (PUM) from India. Manisha has been driving change through her Farmer Producer Organisation (FPO), an organisation that helps members to save costs, achieve fairer prices for their cotton, and develop new ways to boost their income. We sat down with her to learn about her experiences.

Please could you tell us a little bit about yourself?

My name is Manisha Giri, I am 28 years old, and I live in Palodi, a village in the Indian state of Maharashtra. I have been working as a PUM with Better Cotton since 2021, having completed a BSc in Agriculture at the VNMKV University in Parbhani.

As a PUM, my responsibilities include planning, data monitoring, and solving challenges faced by Field Facilitators (FFs). I have oversight on FF training sessions, which are provided to both cotton farmers and cotton workers. I also cross-check with farmers and workers whether minimum wages are being duly paid, whether workers are being forced to work by farmers, whether they are facing any sort of discrimination, and whether there is any pay parity based on gender.

Do you feel like your workplace allows women to thrive?

When I joined, I wasn’t confident, I was always nervous and I questioned myself, as it is a big project. To help me, the Programme Partner team constantly gave examples of the many female Better Cotton staff members in the India team in order to motivate me. They always said that once women are determined to do something, they end up achieving it. When I see women around me fulfilling their personal responsibilities whilst working at a high level, it really motivates me.

What is your proudest achievement?

Getting women together and starting a FPO with them is something I am very proud of. This was a big achievement for me, as gathering women for training and collective action in villages is very difficult. Sometimes, even though the woman wants to participate, their families or husbands don’t allow them.

What other challenges did you face, and how did you overcome them?

We realised that organic carbon in our area was fast depleting and farmers had no livestock anymore, so we zeroed in on making compost for farmers in the FPO. We decided to start with vermicomposting, allowing us to promote sustainable agriculture. Now, 300 female Better Cotton farmers are working with the FPO, and we have reached a point where the demand is so high that we are falling short of vermi beds.

What did you learn from this experience?

As a working woman, I have my own identity even though when I am back home, I continue to take care of my family. I want women to go beyond being recognised as someone’s wife – perhaps eventually men will be recognised as someone’s husband.

What changes do you hope to see in the next ten years?

With the entrepreneurial training sessions that are being conducted, I had set myself a target of getting 32 entrepreneurs trained, and setting up five businesses. However, I have already achieved my three-year target in one year, setting up 30 businesses.

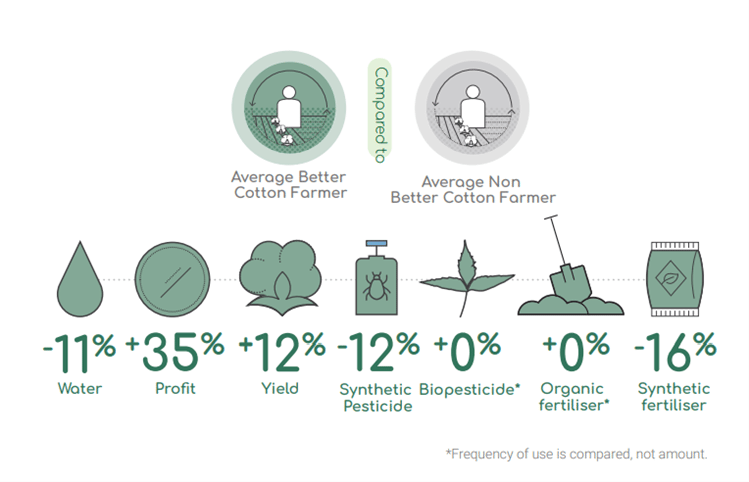

In the next ten years, I expect that people will use exclusively vermicompost, and we will contribute to slowing down climate change. Due to the decreased use of chemical pesticides and increased use of biopesticides, farmers will get increased yield with less expenditure.

I predict that we will have more female staff, and I envision women playing an integral part in decision-making. Women will come to us with ideas to expand their businesses, and they will become independent entrepreneurs.