Geographical Mapping Pilot Launched in Pakistan

Better Cotton works extensively in Pakistan, but traditionally the data we have collected about farmers, producers and partners has not been designed to accurately map their location and activities. This has resulted in supply chain inefficiencies and a lack of new opportunities for those involved in the sector.

A new pilot scheme aims to improve mapping data and thereby rationalise country programming – we sat down with Muhammad Qadeer ul Hussnain, Digital Agriculture Manager at Better Cotton, to find out all about it.

Can you give us an overview of the pilot?

Pakistan has one of the largest numbers of farmers of all Better Cotton-producing countries, spread over 22 districts in two provinces, organised into more than 125 Producer Units (PUs), and managed by six partners. As Better Cotton’s programme has developed, new and increasingly complex questions have emerged.

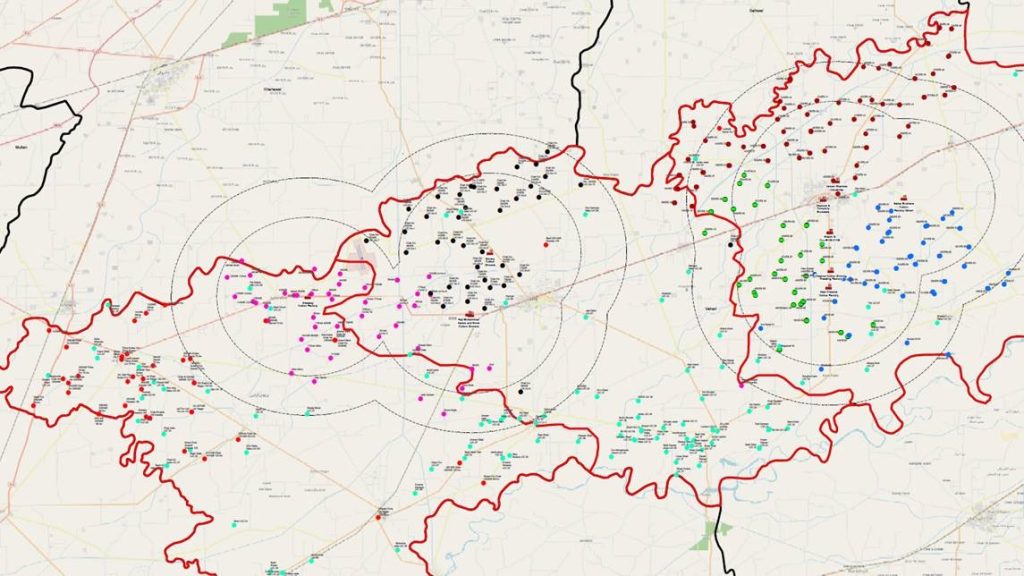

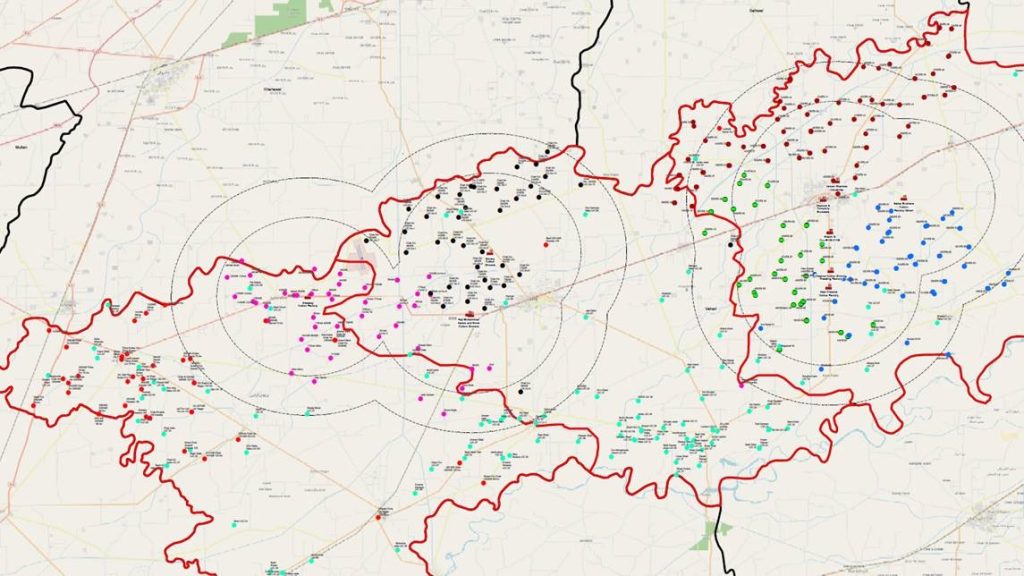

Historically, we’ve relied on tabular data for answers, but now we are adding a geographic dimension to it as well. As a result, Better Cotton is running a pilot to map three districts. Reflecting advances in geographical information system technology, remote sensing and ground data, we opted to turn to geographical mapping for the first time.

The concept was formulated in December 2022, work began to map the districts in question in March, and the pilot will end in July. It is providing customised maps of the three districts resulting in a visual representation of the study area, highlighting factors like the location of the growers, ginners and partners.

What were the pilot’s origins?

Our Pakistan country management team wanted to better assess the organisation’s reach, be able to identify shifting trends in cotton cultivation, and significantly improve data quality. Data is the bedrock of programmes based on numbers, and with different reporting methods and a lack of clarity, we wanted to introduce a system with stronger checks and balances.

For example, we know the districts where farmers work with us, but we lack both exact numbers and the location of those growers who aren’t partnered with the initiative. As a result, we weren’t able to work out why a farmer doesn’t fall under the Better Cotton umbrella. Are they too far from the programme partner in the district? Are they part of a neglected minority? It was previously impossible to tell.

How did you implement the pilot?

This pilot relies heavily on open-source tools, technologies and data sources. Using publicly available material from the Survey of Pakistan (SoP), Open Street Map (OSM), the Election Commission and local government, we’ve created base maps to locate villages where Learning Groups (LGs) are formed.

For ginners, we’ve taken our existing data, like addresses and locations, and plotted these coordinates on the map. Further analysis has been employed to calculate the distances of LGs from the ginners. Laid onto this is satellite imagery, which provides much higher-resolution data and is good for crop mapping. Using an algorithm that highlights the location of fields and references data over five years, we were able to work out where cotton is being repeatedly grown.

Changing how we measure and evaluate our reach in the three pilot districts has resulted in a different sort of thinking. The data creates lots of new possibilities in terms of what we can measure, questions we can ask (particularly of our partners and their activities), as well as potential supply chain benefits. We also need to think about how to realign assessment processes.

What are your initial findings?

The findings are still being collated, but early indications are that the mapping process will provide valuable suggestions to improve country programming, partner management, evaluation and assessment. This, in turn, will result in efficiency gains, cost efficiencies and better programme management.

Our new maps highlight where cotton cultivation has dropped (and so investment does not represent value for money), and where there is a mismatch in partner operations. It also offers potential improvements to the supply chain, for example highlighting to growers the locations of their closest ginners.

What are the pilot’s longer-term goals?

This is a tiny pilot project, but one that may be able to be replicated globally. We’ve devised a methodology that works and we’d like to scale this up. What we’ve created is applicable to the rest of Pakistan, while other countries could use a similar approach.

We plan to develop an atlas of Better Cotton, mapping working areas with programme partners, growers and ginners. In turn, this will highlight the actual scale and reach of our operations, while also offering new and improved opportunities to partners and helping improve supply chain coordination.

Read more