The Better Cotton Chain of Custody (CoC) Standard v1.0 introduces new physical CoC Models in addition to Mass Balance to enable the tracing of Physical (also known as Traceable) Better Cotton as it flows through the supply chain.

To be able to source Physical Better Cotton, supply chain organisations need to be onboarded to the new CoC Standard. If your organisation is interested in implementing the physical CoC models at your site(s), please find more information on how to start the onboarding process here.

Chain of Custody Model Supply Chain Application

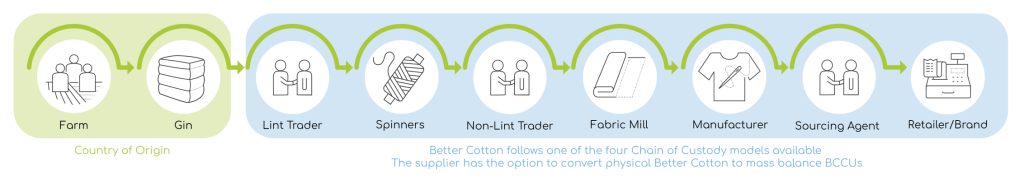

From the farmers who grow Better Cotton to the companies that source it, the Better Cotton CoC is the documentation and evidence of Better Cotton as it moves through the supply chain. The image below illustrates how are the four CoC models included in our CoC Standard applicable to different stages of the supply chain.

Segregation (Single Country) is applicable at the farm and ginner level of the supply chain. Segregation (Single Country) and Mass Balance are applicable at the raw cotton trader level of the supply chain. For the rest of the supply chain all CoC supply chain models, or a combination of CoC supply chain models are possible, including the existing Mass Balance model. Better Cotton Retailer and Brand members may source all CoC models.

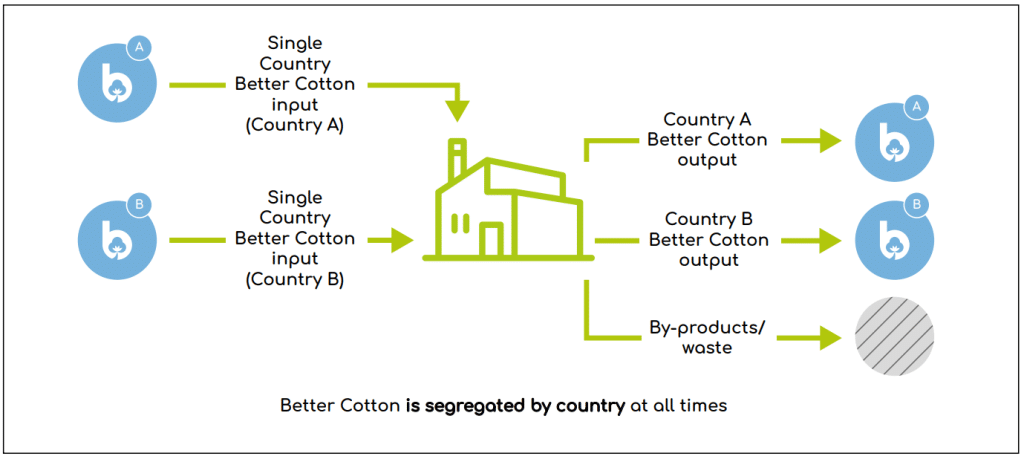

Segregation (single country)

Segregation (single country) requires separation of Physical Better Cotton and conventional cotton from the farm level onwards and does not allow mixing or substitution between Physical Better Cotton of different origins and conventional cotton of any origin, throughout the supply chain. All organisations applying this model shall ensure that Physical Better Cotton material from a single country is kept physically separate from all other cotton sources, including material from different Better Cotton production countries.

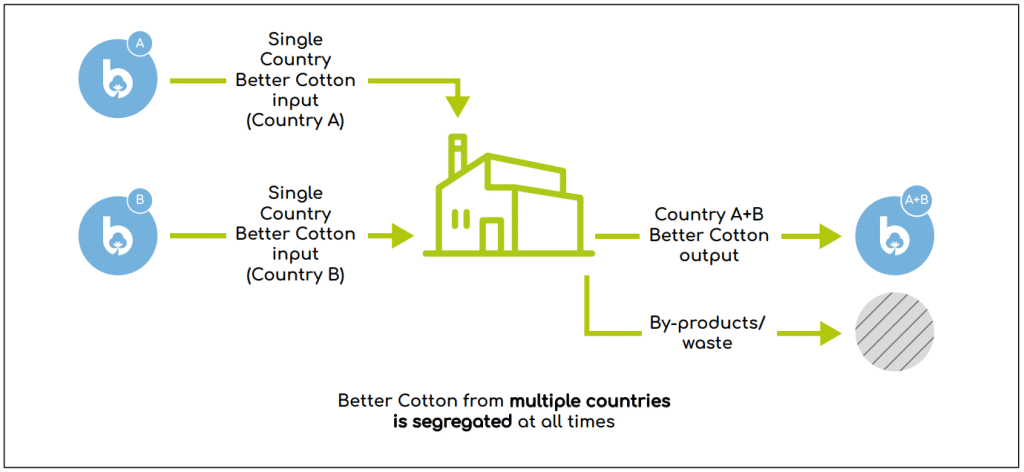

Segregation (multi-country)

Segregation (multi-country) requires the separation of Physical Better Cotton and conventional cotton from the farm level onwards and does not allow mixing or substitution between Physical Better Cotton and conventional cotton throughout the supply chain. The model is applied when the Physical Better Cotton originates from multiple (more than one) countries.

Controlled Blending

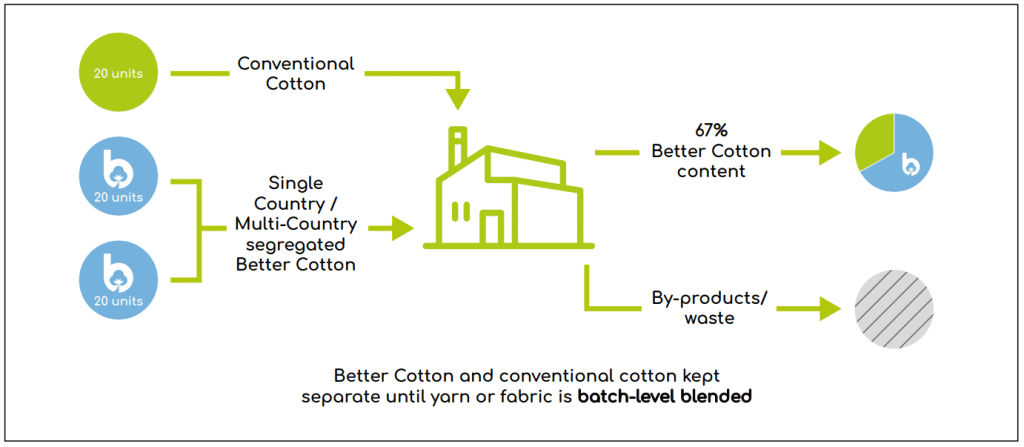

Controlled Blending is being introduced to assist supply chains in making the transition to sourcing and selling Physical Better Cotton by anticipating that demand may at times exceed supply.

The model allows the mixing of Physical Better Cotton and conventional cotton within a production batch, resulting in a percentage claim about the proportion of physical Better Cotton used within the batch. Conventional cotton may include recycled, regenerative, organic, in-conversion, and any other cotton input that is sourced in accordance with the Better Cotton Platform (BCP) Terms and Conditions.

The model may only be used within a manufacturing or processing activity from a spinning mill onwards. It cannot be used for the trading and/or distribution of Better Cotton products or where there is trade without physical possession of products. Those trading or distributing cotton processed under the Controlled Blending CoC model shall maintain segregation and physical identification of the product when in their custody.