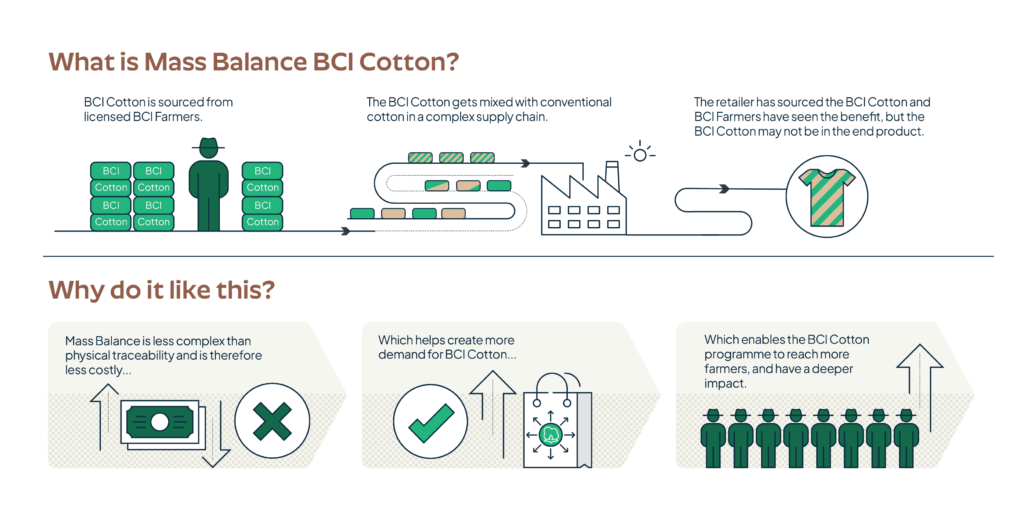

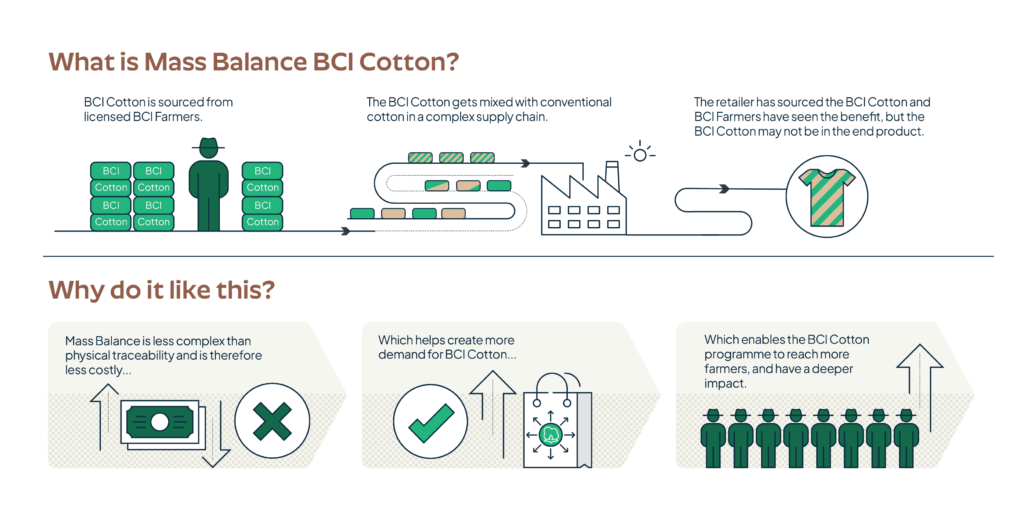

Mass Balance is a volume-tracking system that allows BCI Cotton to be substituted or mixed with conventional cotton by traders or spinners along the supply chain while ensuring that the amount of BCI Cotton sold never exceeds the amount of BCI Cotton purchased at all levels in the textile supply chain. It can be implemented from ginner onwards.

Segregation Model

Between the farm and gin, BCI Cotton seed cotton and lint bales are always required to be segregated from other types of cotton. The BCI Standard System requires a product segregation chain of custody model. This means that farmers and ginners need to store, transport and process BCI Cotton separately from any conventional cotton.

This ensures that all BCI Cotton bales produced by participating gins are 100% BCI Cotton.

How does the Mass Balance system work?

To monitor the volume of BCI Cotton in the supply chain, each kilogram of BCI Cotton lint from the gin is assigned one BCI Cotton Claim Unit (BCCU). As the cotton moves along the supply chain and is made into different products, these BCCUs move along with it to show the amount of BCI Cotton in each order. The volumes of BCCUs allotted to BCI Cotton orders are tracked on the BCI Platform.

As BCCUs are not connected to the original BCI Cotton sourced from BCI Farmers, BCI Cotton is not traceable to its country of origin. However, Mass Balance helps to simplify the complexity of cotton, textile and apparel supply chains while still delivering direct benefits to farmers, and will remain an important part of our offering alongside Physical BCI Cotton.